MODEL RANGE OF “BENT-IRON” SOLID FUEL STEAM GENERATORS

Nominal steam output: 1500 kg/h

Output modulation: 30-100%

Thermal power: 1000 kW

Operating pressure: 3-15 bar

Efficiency: 86±1%

Steam type: saturated (superheated optional)

Time to reach operating mode: 25-40 min

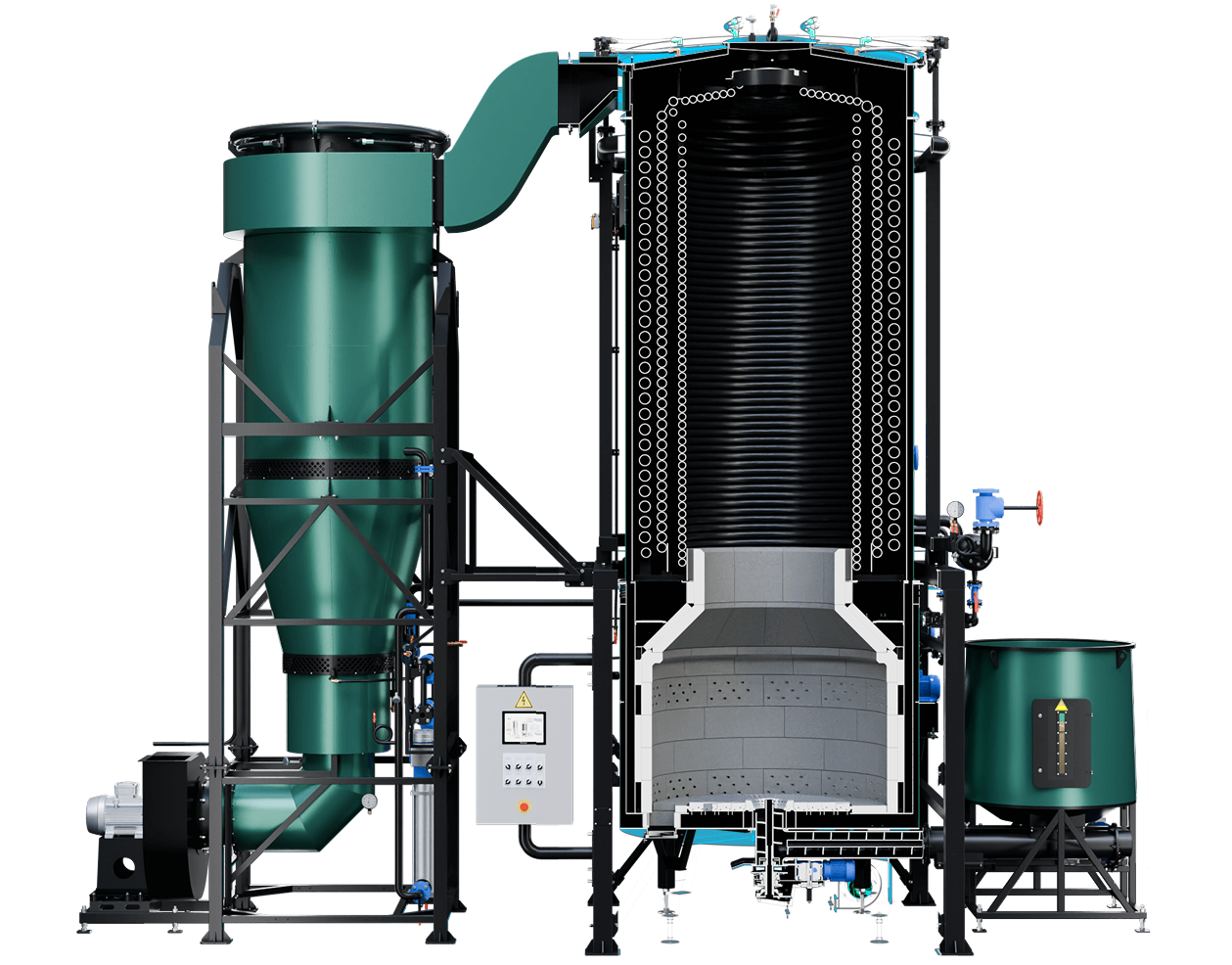

Heat exchanger cleaning system: automatic, pneumatic-pulse

Ash removal system: automatic air-assisted

Cyclone-economizer: yes, separate module

W = 5600 mm

L = 3300 mm

H = 4900 mm

± 20 mm

Wood pellets

Wood pellets

ISO 17225-2:2021

130 ± 20 kg/t of steam

Wood chips

Wood chips

ISO 17225-4:2021

190 ± 20 kg/t of steam

Nominal steam output: 2500 kg/h

Capacity modulation: 30-100%

Thermal power: 2000 kW

Operating pressure: 3-15 bar

Efficiency: 86±1%

Steam type: saturated (superheated optional)

Time to reach operating mode: 30-45 min

Heat exchanger cleaning system: automatic, pneumatic-pulse

Ash removal system: automatic air-assisted

Cyclone-Economizer: yes, separate module

W = 7096 mm

L = 3837 mm

H = 5950 mm

± 20 mm

Wood pellets

Wood pellets

ISO 17225-2:2021

130 ± 20 kg/t of steam

Wood chips

Wood chips

ISO 17225-4:2021

190 ± 20 kg/t of steam

Nominal steam output: 5000 kg/h

Capacity modulation: 30-100%

Thermal power: 4000 kW

Operating pressure: 3-15 bar

Efficiency: 86±1%

Steam type: saturated (superheated optional)

Time to reach operating mode: 30-50 min

Heat exchanger cleaning system: automatic, pneumatic-pulse

Ash removal system: automatic air-assisted

Cyclone-economizer: yes, separate module

W = 7300 mm

L = 3800 mm

H = 7100 mm

± 20 mm

Wood pellets

Wood pellets

ISO 17225-2:2021

130 ± 20 kg/t of steam

Wood chips

Wood chips

ISO 17225-4:2021

190 ± 20 kg/t of steam

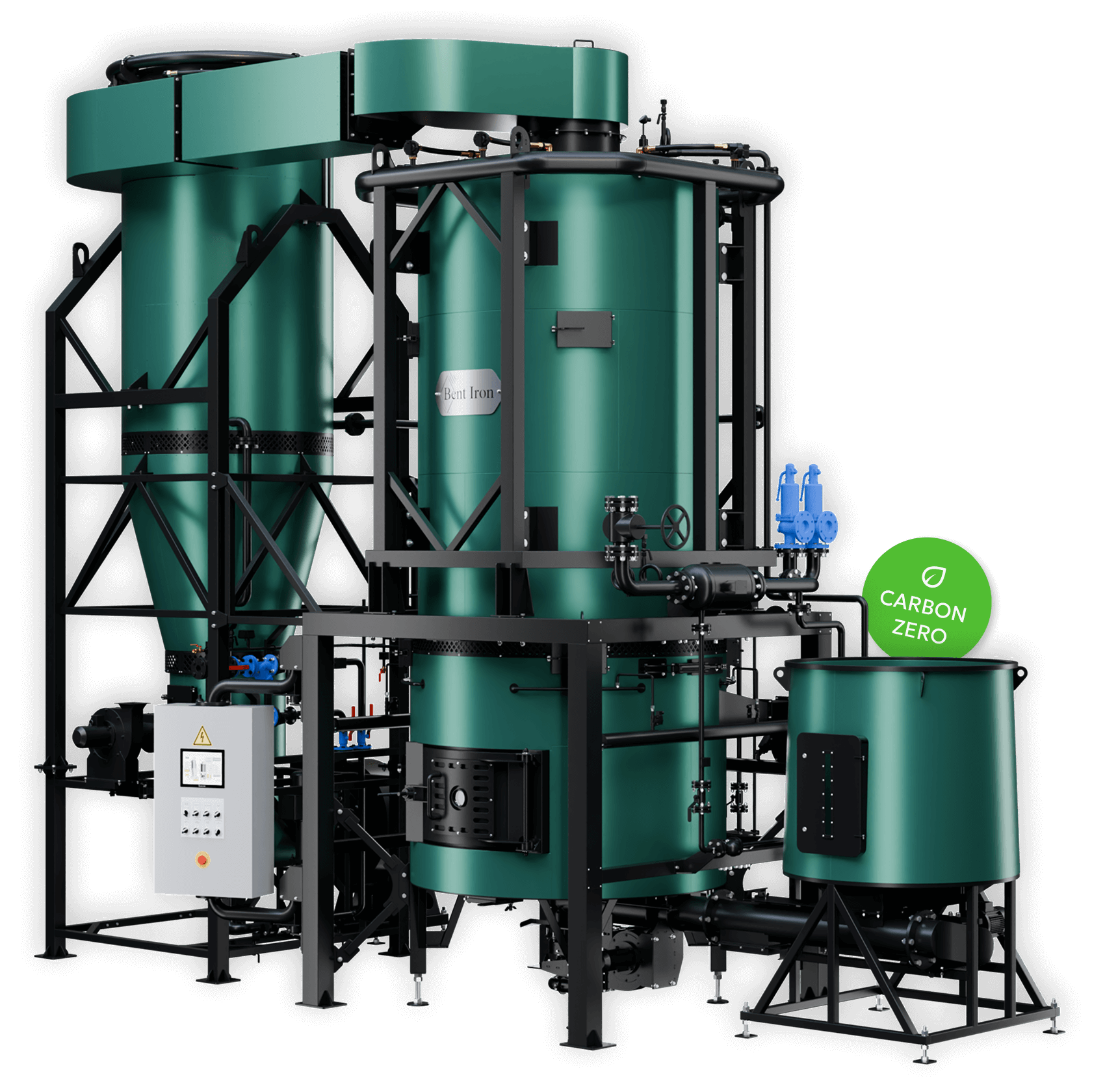

TURNKEY SOLUTION

HIGH OPERATIONAL EFFICIENCY

Bent Iron IN POLAND: REAL RESULTS AND EFFICIENCY

Model: Bent Iron BS(S) 2.0

Location: «Saltowski» Meat Processing Plant, Lniano, Poland

Fuel: wood pellets

Savings: over 50% in costs

Steam: stable, without pressure drops

Compliance with EU environmental standards

MARKET LEADERS TRUST US

FOR THEIR STEAM SUPPLY

COMPREHENSIVE SUPPORT PACKAGE